What is iso 16949 ?

IATF 16949:2016 (replaces ISO/TS 16949:2009) is a standard that establishes the requirements for a Quality Management System (QMS), specifically for the automotive sector. The ISO/TS 16949 was originally created in 1999 to harmonize different assessment and certification schemes worldwide in the supply chain for the automotive sector. The primary focus of the IATF 16949 standard is the development of a Quality Management System that provides for continual improvement, emphasizing defect prevention and the reduction of variation and waste in the supply chain. The standard, combined with applicable Customer-Specific Requirements (CSR’s), define the QMS requirements for automotive production, service and/or accessory parts. IATF 16949:2016 is an independent QMS standard that is fully aligned with the structure and requirements of ISO 9001:2015. Therefore, the IATF 16949 cannot be implemented alone as a stand-alone document, but must be implemented as a supplement and in conjunction with ISO 9001:2015.

A Quality Management System based on IATF 16949:

- Is a method of defining how an organization can meet the requirements of its customers and other stakeholders

- Promotes the idea of continual improvement

- Requires organizations to define objectives and continually improve their processes in order to reach them

- Emphasizes defect prevention

- Includes specific requirements and core tools from the automotive industry

- Advanced Product Quality Planning (APQP)

- Failure Mode and Effect Analysis (FMEA)

- Statistical Process Control (SPC)

- Measurement System Analysis (MSA)

- Production Part Approval Process (PPAP)

- Promotes reduction of variation and waste in the supply chain

- Requires documented and implemented corporate responsibility polices

The IATF 16949 standard provides guidance and tools for companies and organizations who want to ensure that their products consistently meet customer requirements and that quality and customer satisfaction are consistently improved. The IATF 16949 standard is applicable to sites of the organization where manufacturing of customer-specified production parts, service parts, and/or accessory parts occur.

The standard is based on seven Quality Management Principles, including a strong customer focus, the motivation and implication of top management, the process approach and continual improvement.

These Quality Management Principles are defined as follows:

- Customer focus

- Leadership

- Engagement of people

- Process approach

- Improvement

- Evidence-based decision making

- Relationship management

WHY CHOOSE ISO 16949?

Implementing IATF 16949 ensures that customers receive consistent, good quality products and services, which in turn may bring many business benefits. IATF 16949 specifies requirements for a Quality Management System when an organization wants to:

- Demonstrate its ability to consistently provide products that meet customer and applicable statutory, regulatory and product safety requirements

- Enhance customer satisfaction through the effective application of the system

- Implement processes for improvement of the system

- Define overall context, who is affected and what they expect

- Clearly state objectives and identify new business opportunities

- Put customers first, making sure their needs are consistently met and enhance their satisfaction

- Have repeat customers, increase customer loyalty, add new clients and increase business

- Expand into new markets, as some sectors and clients require IATF 16949 before doing business

- Identify and address the risks associated with your organization

- Work in a more efficient way to increase productivity and efficiency, bringing internal costs down

- Become more socially responsible through the documentation and implementation of corporate responsibility polices

HOW MUCH DOES ISO 16949 COST?

The cost of certification depends on several factors. These include your business sector, type of organization, number of clients, suppliers, your scope of work, and your number of employees. Moreover, costs vary as per industry specific accreditation as well (such as from EGAC, EIAC, IAS, DAKKS, UKAS, JAS-ANZ or NABCB).

However, QA INTERNATIONAL SERVICES is committed to provide a cost-effective route to ISO 16949 certification. That’s why we focus on making ISO certification simple and straightforward. We save you money because we spend less time creating complex document trails and more time building a system that works for your business.

AN ISO 16949 IMPLEMENTATION?

Implementation & complying the requirements of the IATF 16949 standard can be done at any time but is typically used when:

- Customers specify this requirement as part of the contract

- Organizations want to improve their products and customer satisfaction.

Organizations’ deciding to implement ISO 16949 or improved QMS is a strategic decision. All efforts should be focused on the identification and minimization of risk while meeting and exceeding customer and organizational goal and objective requirements.

Organizations should make a commitment to:

- Recognize direct and indirect customers as those who receive value from the organization

- Understand customers current and future needs and expectations

- Link the organization’s objectives to customer needs and expectations

- Communicate customer needs and expectations throughout the organization

- Plan, design, develop, produce, deliver and support products to meet customer needs and expectations

- Measure and monitor customer satisfaction and take appropriate actions

- Determine and take actions on interested parties needs and expectations that can affect customer satisfaction

- Actively manage relationships with customers to achieve sustained success

- Become more socially responsible

- Provide necessary resources to ensure product safety requirements are met.

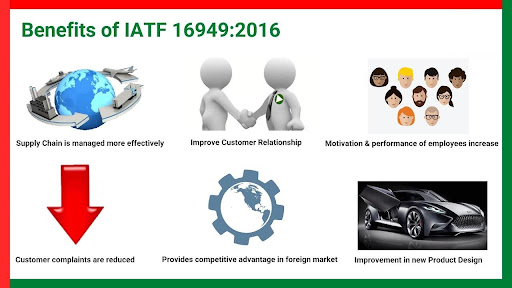

BENEFITS OF ISO 16949 FOR YOUR ORGANISATION?

Although, IATF certification delivers numerous advantages for automotive suppliers willing to make the necessary investment. The benefits of IATF 16949 certification for the automotive industry focus on seven main areas:

- Credibility

- Global reach

- Customer satisfaction

- Process integration

- Evidence-based decision making

- Continual improvement culture

- Employee engagement